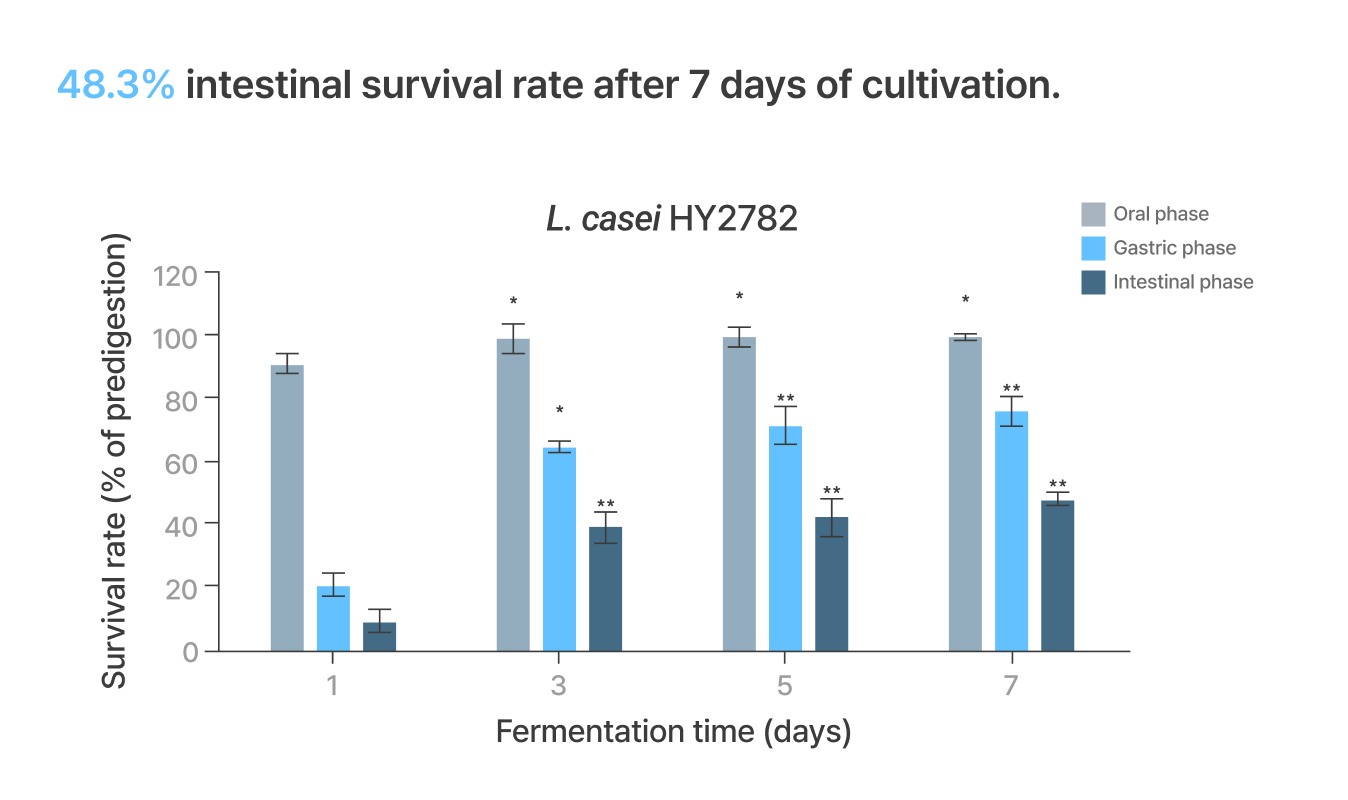

Source : Appl. Sci.. 2021, 11, 2481

Source : Appl. Sci.. 2021, 11, 2481

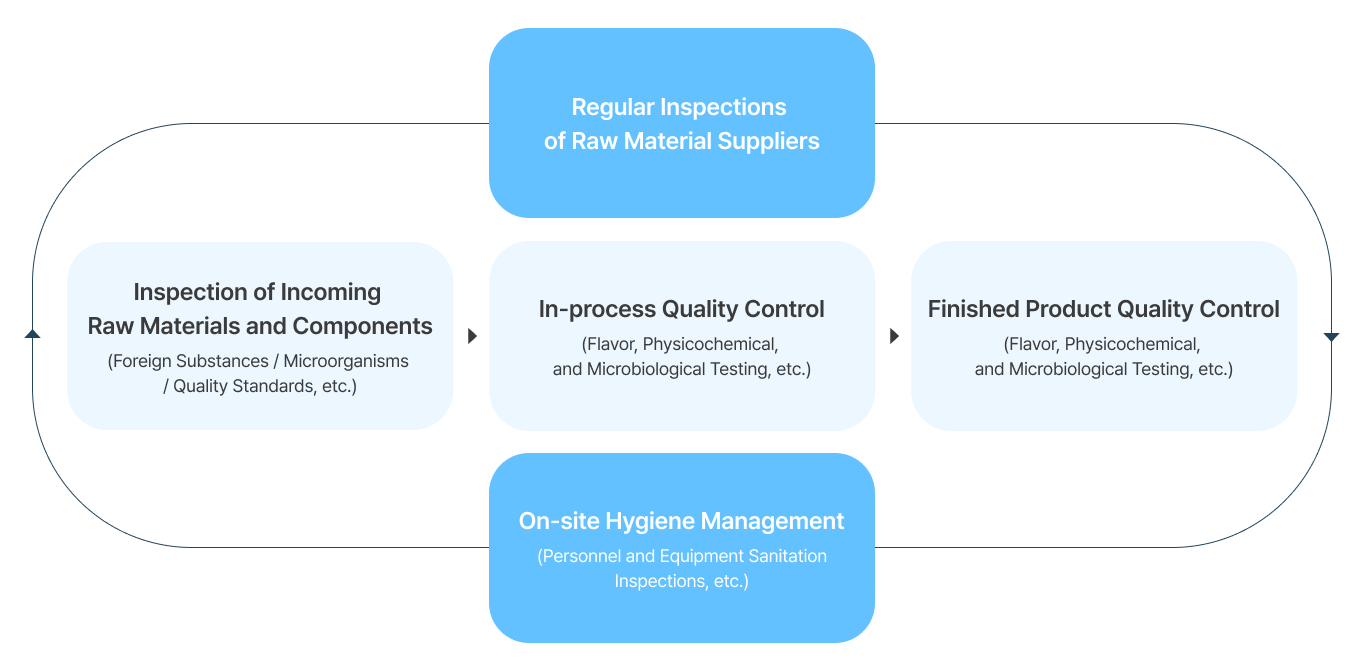

Supporting your health every day through safe and clean practices.

Udeok Chairman Yoon Deok-byeong

Annual Base Liquid Production

Annual Container Molding Volume

Annual Product Output